Flowfinity Actions 23.1 Provides New Capabilities for Industrial IoT and M1 Controller

June 22, 2023, by Alex Puttonen

The latest upgrade to Flowfinity brings a number of improvements and enhancements to the Flowfinity M1 IoT controller in addition to UI and dashboard updates.

We've covered new Fast Track IO capabilities that allow you to measure sensor activity with sub-millisecond accuracy in our previous blog post.

Now, let's dive into additional updates in 23.1 as related to the M1 controller.

Enhanced Battery Support

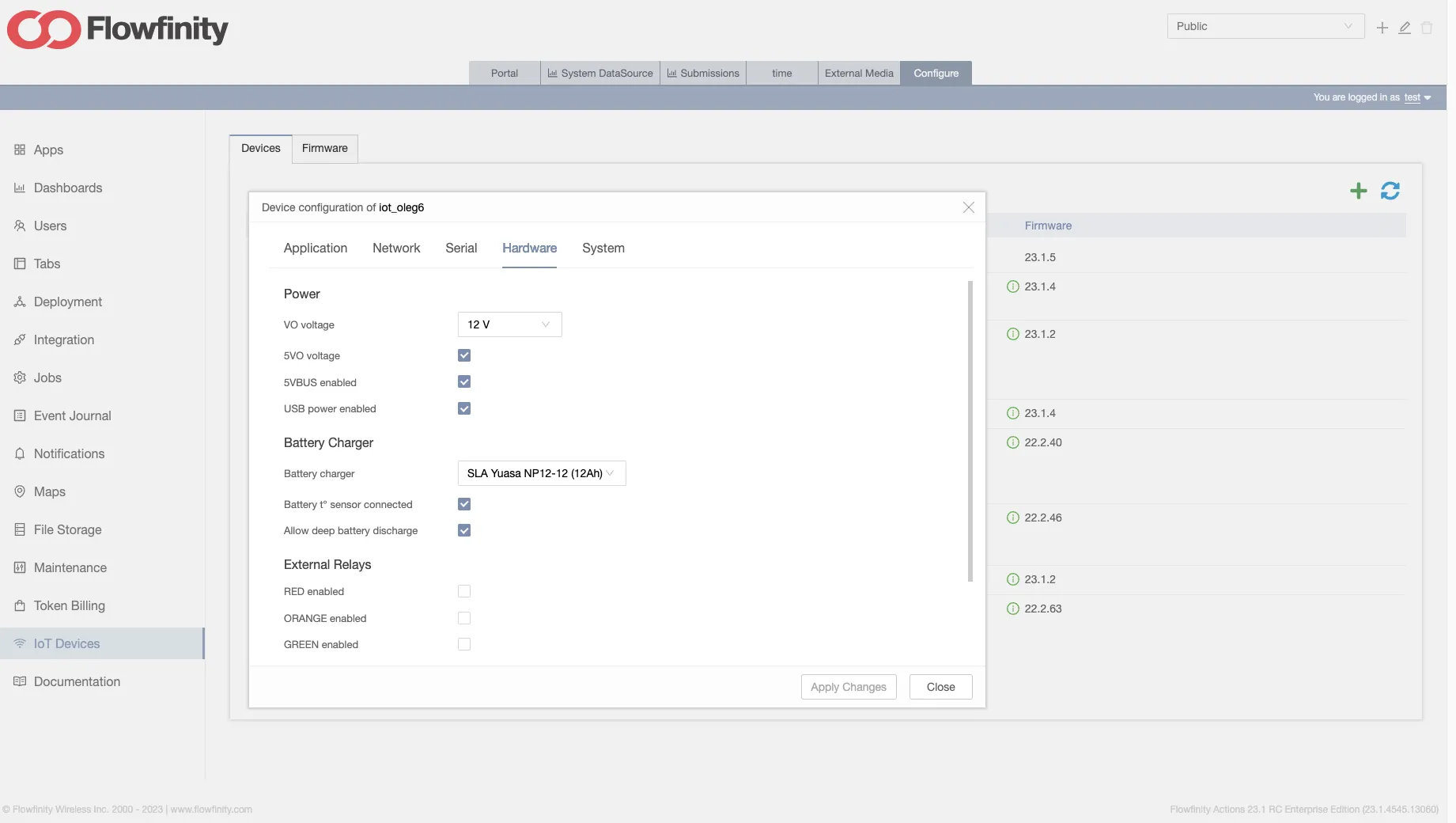

The Flowfinity M1 now supports new battery types, including Yuasa NP12-12, Power Sonic PSL-SC-1270, and PSL-SC-12120. Connector adapters for these batteries are now included with your Flowfinity M1, so that using a back-up power source to ensure uninterrupted operation in the event of an outage is simple and convenient.

Yuasa batteries are traditional sealed lead-acid (SLA) chemistry AGM batteries that provide cost efficient battery backup for the built in UPS of the Flowfinity M1 controller. The newly supported Yuasa NP12-12 is a high-capacity battery allowing Flowfinity M1 controller to operate for blackout periods exceeding 24 hours on battery power. Like the smaller Yuasa NP7-12 these AGM batteries can be used in below freezing temperatures.

The two newly supported Power Sonic batteries employ LiFePO4 chemistry, otherwise known as LFP. These batteries are inherently safe and highly stable compared to other lithium battery chemistries, offering lightweight flexibility and an extended number of charge-discharge cycles compared to SLA batteries. It's important to note, however, that LFP batteries can only be used above freezing temperatures. Provided the optimal operating temperature they can be expected to provide a similar run time to the Yuasa NP7-12 and NP12-12 respectively.

Battery type configuration is now mandatory in the Flowfinity IoT device manager. It is important to select the battery type that corresponds with the actual battery connected to each controller for optimal performance.

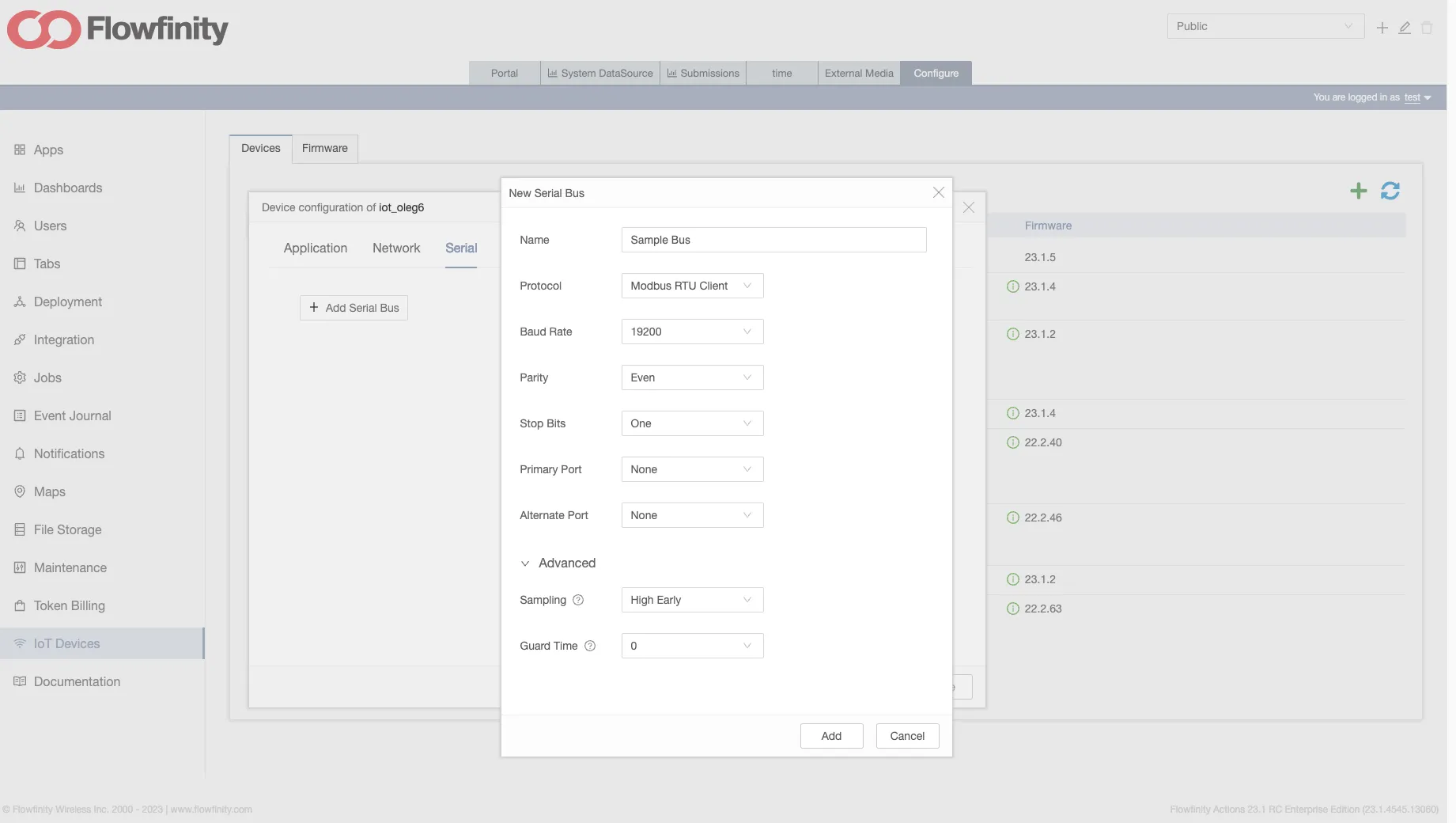

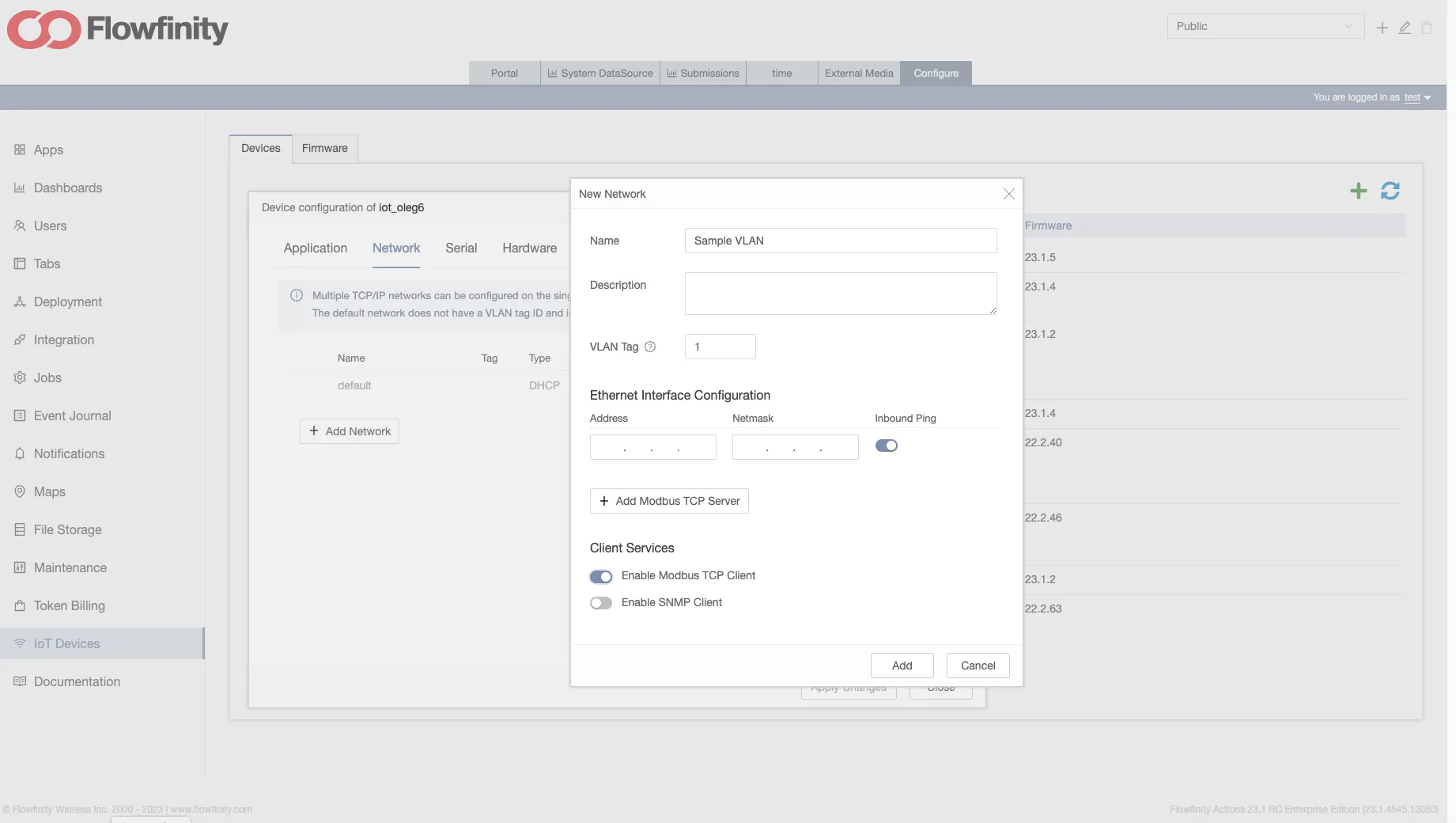

Modbus Client and Server Configuration

The Flowfinity Actions 23.1 also introduces the capability to configure a Modbus client and server from the device manager. This applies both to Modbus RTU over RS-485 serial bus and Modbus TCP over Ethernet.

The Modbus client is typically used for querying remote digital sensors for sampled values. The Modbus server can be used to turn the Flowfinity M1 controller into a remote sensor that serves data to a remote Modbus client. These capabilities can also be used for control actions, e.g. for controlling state of relays.

An exciting additional feature is the ability to network two Flowfinity M1 controllers so that one operates as a Modbus server and the other as a Modbus client. This configuration is supported over both RS-485 serial communication and Modbus TCP. When networked this way, Flowfinity M1 controllers can exchange data with each other independent of Flowfinity Actions server connectivity.

To isolate Modbus TCP traffic from your internal or Internet-facing network, the Flowfinity M1 allows you to configure one or more VLANs on its Ethernet port. We recommend using this capability together with a managed Ethernet switch to keep all Modbus TCP communication on separate "device networks."

New App Configuration Templating Technology

Flowfinity Actions 23.1 introduces app configuration templating technology, allowing the dynamic configuration of the controller based on runtime data. The configuration data records can be received from Flowfinity Actions or another data source.

This means monitors for sampling sensors can be dynamically configured based on sensor metadata records received from the Flowfinity Actions database. This empowers you to design highly configurable IoT apps that adapt to specific sensor deployments, adding a new dimension of flexibility to save time and effort going forward.

Simplified IoT App Authoring

Flowfinity Actions 23.1 also simplifies IoT app creation with new capabilities for frequently used tasks such as signal debouncing. There are also additional aggregation functions like "min/max", "avg/median", and "sum" for on-controller sensor data aggregation at the edge.

Conclusion

Flowfinity Actions 23.1 coupled with the natively compatible M1 Controller is a significant update for industrial IoT monitoring and control. With enhanced battery support, streamlined Modbus client and server configuration, innovative app configuration templating technology, and simplified app authoring, it's never been easier to optimize your IoT experience.

Contact our experts to explore how you can deploy custom IoT solutions for your use case.