Real-Time Operational Intelligence Is Achievable for Manufacturers with Flowfinity IoT Solutions

April 11, 2024, by Alex Puttonen

Introduction

It's often said you can't improve what you don't measure. In modern manufacturing, Operations Managers are strategic thinkers tasked with improving processes, predicting future challenges, and reacting quickly to threats or anomalies. All while keeping an eye on the bottom line. Making decisions based on gut feelings doesn't cut it anymore.

According to a 2022 survey by the Society of Manufacturing Engineers, 77% of respondents believe innovative technology, such as IoT and real-time Operational Intelligence (OI) will increase their organizations' competitiveness. However, many think they lack the resources and expertise to access and benefit from this technology.

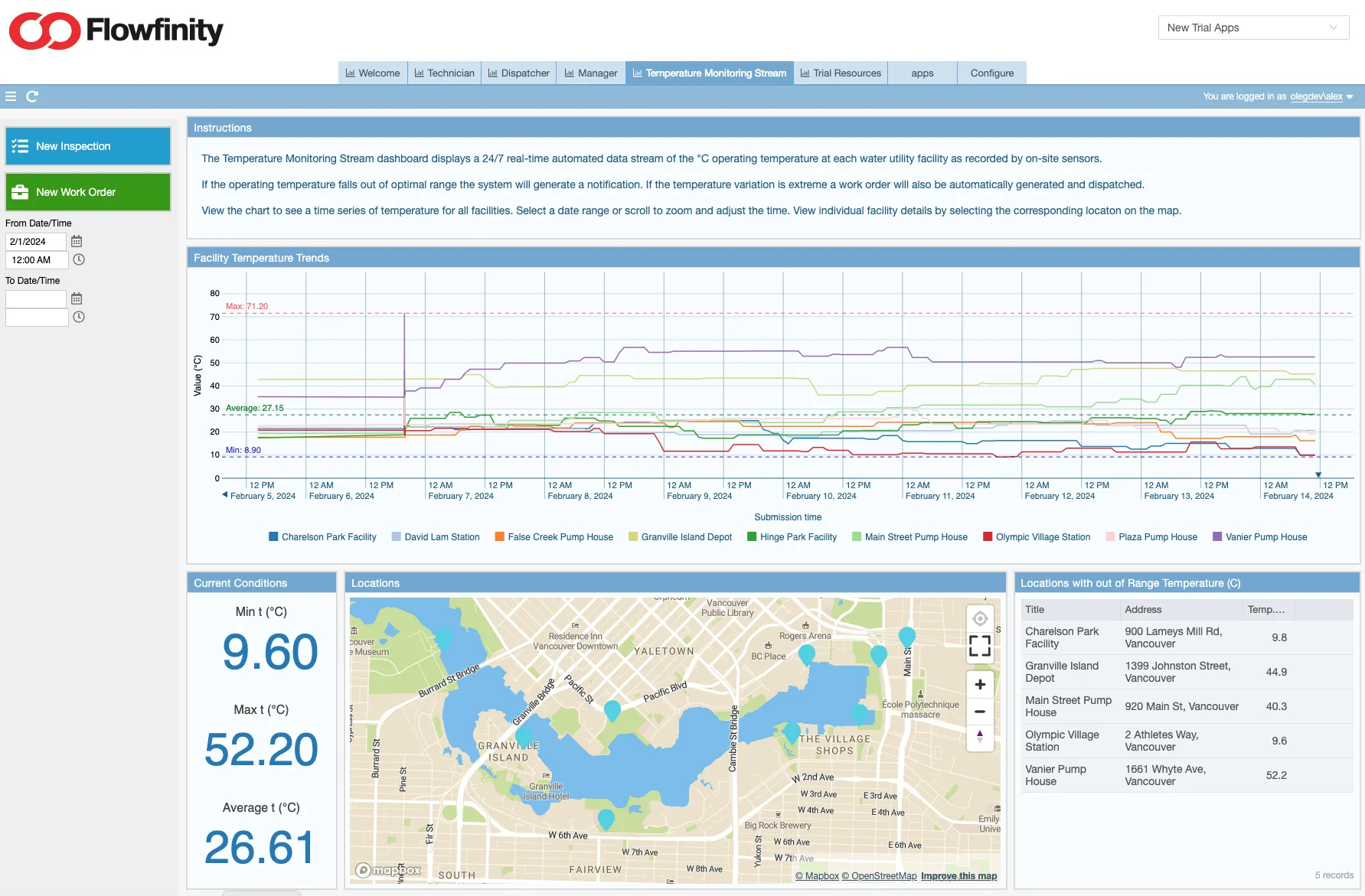

Flowfinity is helping organizations of all sizes access and scale this technology to gain a competitive advantage by offering customizable OI Dashboards connected to IoT data and human driven workflows. Now, you can provide real-time insights without needing to program complex and expensive hardware and software to be compatible.

Operational Intelligence vs Business Intelligence

While OI and BI Dashboards both provide valuable insights, they cater to different needs. OI Dashboards are critical for optimizing day-to-day operations in real-time, whereas BI Dashboards are better suited for analyzing historical trends. BI dashboards generally can't proactively monitor, alert, or take corrective action if anomalies occur.

Amazon Web Services defines Operational Intelligence as "The process of collecting and analyzing real-time operations data to monitor system health and pre-emptively reduce issues. With the introduction of the Internet of Things (IoT) and smart sensors, OI now includes the real-time monitoring of real-world operations such as pipelines, machinery, and energy equipment."

Flowfinity provides true real-time Operational Intelligence dashboards that can be integrated with your workflows without code. All Flowfinity hardware and software are designed to work together out of the box with the option to stream high-frequency IoT data into an optimized time series database. Plus, you can connect your Flowfinity data with popular tools such as Power BI to perform historical analysis if desired.

The Importance of Real-Time Data in Operations

The need for immediate insight to take immediate action has never been more critical. Flowfinity’s OI dashboards deliver real-time data that allows for swift identification of issues, enabling managers to act before minor hiccups become significant disruptions.

Data is collected from people in the field or on the floor using mobile apps customized to your business processes. Or, streamed directly into your database from sensors that can be retrofitted to your facilities using fully compatible Flowfinity M1 IoT controllers.

The true power of real-time data is its ability to transform reactive operations into proactive ones. With access to up-to-the-minute data managers can predict trends, prepare for potential impacts, and adjust resources as needs evolve. This shift from reactive to proactive prevents losses and unlocks efficiency to drive growth.

Critical Benefits of Operational Intelligence Dashboards

Real-time Monitoring and Alerting: OI dashboards provide a live view of business operations allowing users to monitor processes and activities as they happen. An OI dashboard can continuously monitor the production line for equipment performance, production speed, product quality, and environmental conditions.

For instance, if a particular machine starts operating outside its normal temperature range, it could indicate an impending failure, such as overheating due to a worn-out component or insufficient lubrication.

This real-time capability ensures potential issues can be identified and addressed promptly, minimizing downtime and operational disruptions.

Enhanced Decision Making: By aggregating and visualizing data from various sources, these dashboards present complex information in an easily digestible format. Consider a highly regulated food production facility that processes chicken or other agricultural products facing the challenge of maintaining high product quality while maximizing yield.

An OI dashboard helps management visualize real-time data from the processing line, including defeathering, weighing, and packaging. Key metrics include processing times, temperatures, line speeds, and yield, as well as compliance alerts for health and safety.

By gaining access to real-time production data the plant can make dynamic adjustments to processing conditions to help maximize yield and ensure high product quality, directly impacting profitability. In addition, continuous monitoring helps ensure that all product complies with health and safety regulations, reducing the risk of costly recalls and enhancing brand reputation.

Increased Operational Efficiency: Operational Intelligence dashboards highlight inefficiency within business processes. Specific industries such as paper manufacturing, chemicals, and utilities can be highly energy intensive. Therefore, energy consumption and prices can have a massive impact on profitability.

An OI dashboard is configured to monitor energy usage, collecting data from sensors that measure electricity and fuel consumption, temperatures, pressures, and flow rates. By visualizing and analyzing this data; managers can identify patterns of inefficiency and make targeted adjustments for immediate energy savings and long-term efficiency.

As a result, the manufacturer can maintain competitive pricing due to lower production costs, improve profitability, and contribute to environmental conservation efforts.

Better Collaboration: Dashboards provide a unified view of data that multiple stakeholders across the organization and supply chain can access. A window manufacturer operates within a complex supply network involving raw material suppliers, manufacturing units, distribution channels, and end clients.

They could design an OI dashboard that integrates data from design and engineering, supplier inventories, production schedules, quality control, and customer orders. This dashboard would be accessible by all internal teams and to a certain extent, by external partners such as key suppliers and construction firms for just in time delivery.

With a shared view of supply and demand, the manufacturer and its suppliers can work more closely to ensure that materials are available when needed, minimizing bottlenecks. This shared access facilitates better communication, as teams can work together more effectively, using the same data insights to drive operations forward and provide up-to-date communication about order statuses and lead times to build trust with customers.

Conclusion

Real-time data is not a luxury; it's a necessity for modern operations management. Operational Intelligence is essential for businesses seeking to optimize production. They enable real-time monitoring, enhance decision-making, improve efficiency, provide predictive insights, foster collaboration, and support risk management.

Flowfinity is the only platform that provides a fully customizable solution that you can configure and integrate with your systems to be retrofitted to your existing facility, from end-point sensors to servers and real-time OI dashboards.

Now, you can connect your people, processes, and machines without the need to custom code hardware and software. Data can be collected using Flowfinity Streams optimized high-volume database to scale and accommodate growing IoT data volumes, ensuring your business can continue gaining valuable insights as you expand.

Contact our experts for a complimentary consultation. We'll help you overcome barriers to entry and upgrade your facility with real-time Operational Intelligence!