Flowfinity Introduces Business Process Automation… at the Edge

Sept 15, 2021, by Sean King

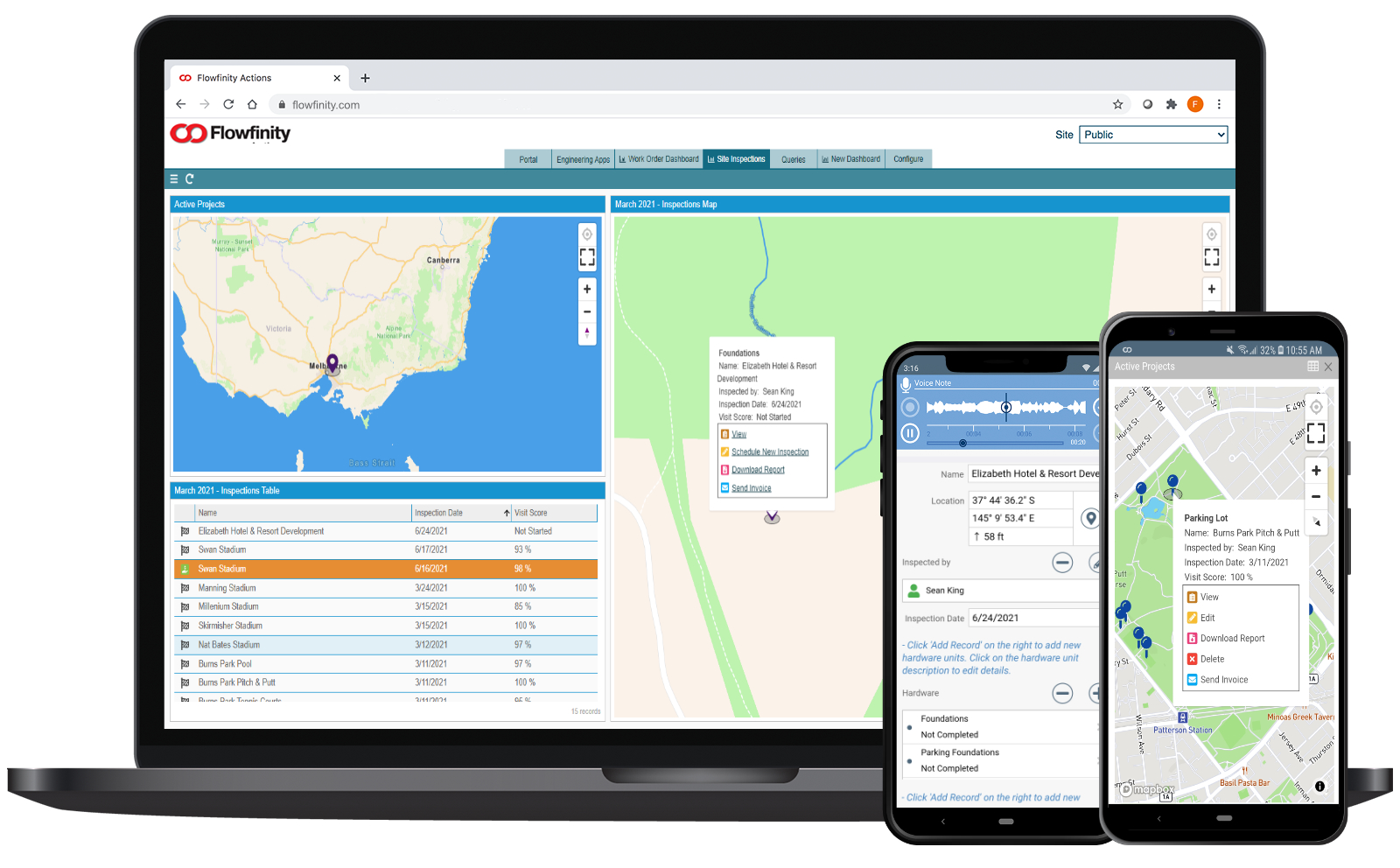

At Flowfinity, our goal is to empower you with tools to create and automate your business without code. Traditionally, our no-code platform has enabled digital data collection driven by mobile devices and augmented with workflow automation executed by software robots.

In our latest release, we've introduced support for Internet of Things (IoT) devices. Now you can supplement people-driven processes by connecting physical assets directly to digital workflows 24/7 for monitoring, analysis, and control.

Let's take a deeper look at the game-changing functionality announced in Flowfinity Actions 21.2!

Business Process Automation… at the Edge

The Internet of Things is all about connecting and monitoring the physical world as part of digital workflows. We've all seen demonstrations of smart home devices as an application of IoT technology, perhaps automated lighting systems or a "smart" refrigerator.

But there is more to IoT than just automating consumer electronics for domestic convenience! Let's consider how organizations can benefit from this new technology.

For many businesses, it is more helpful to think about the Industrial Internet of Things (IIoT).

Industrial IoT is about connecting physical assets to their digital business processes using sensors, controllers, or other internet-enabled devices.

These devices, sensors, and controllers record and transmit data about the internal state, external environment, or the operational status of assets such as machinery or industrial equipment. For example, the ambient and internal temperature of an industrial freezer. Or the operational status of a piece of manufacturing equipment.

When coupled with no-code tools that simplify configuration and connectivity issues, Industrial IoT technology empowers organizations to achieve 24/7 asset monitoring at a fraction of the cost and complexity of traditional Operation Technology (OT) systems.

Taking real-time data about assets, e.g., internal & external temperature or status, and feeding this directly into your digital workflows provides an unprecedented level of insight into their operations.

And combining this continuous data collection with sophisticated workflow capabilities and data-processing software robots will take business process automation to a new level.

This live operational and environmental information also offers organizations a new way to approach asset management and maintenance. Rather than arbitrarily scheduling maintenance based on a set time interval, managers can focus their inspection and maintenance efforts on assets that reliable real-time data suggests are a higher priority. For example, managers can prioritize any asset operating at the higher end of the acceptable internal temperature range for an extended period.

Moving from reactive to proactive maintenance and asset management can help every firm save time and money, but particularly those with assets in remote or hard-to-reach locations.

There is also a significant automation benefit to deploying IoT devices. Using business logic, managers can automate workflows based on sensor or controller data, allowing an organization's people to oversee workflows rather than processing and actioning routine data-processing or administrative tasks.

This real-time data will also level up monitoring and reporting, providing management teams with all their operational data in interactive dashboards. With all enterprise data tied together in a central hub, managers can assign people-driven tasks, such as manual asset inspections, instantly from the same dashboard that curates asset data.

These IIoT benefits help organizations augment their people-driven workflows, allowing almost any enterprise to improve workflow automation and data collection. But for some organizations, insight alone is not enough… action is needed!

And this is where edge computing comes in.

Edge computing is about more than capturing and transmitting data, it's about moving decision-making out from central databases out to these IoT controllers on the 'edge' of workflows.

It's useful to think about edge computing as sitting on top of IoT infrastructure, taking the real-time data capture and monitoring capabilities, and adding the ability to act. However, not all IoT devices are capable of edge computing. IoT Controllers, as opposed to simple sensors, are required to process data out at the edge. Configuring these controllers and connecting to your systems has been a significant challenge and a major barrier to entry for IoT deployments.

Now Flowfinity provides support for devices so you can connect your physical assets to digital workflows. This will empower innovative business leaders to gain efficiency and reduce latency by adding edge computing to their new IoT data streams without complex and costly code.

As with many technological breakthroughs, there are such a wide variety of possible applications it can be difficult for even forward-thinking organizations to understand the full extent of what IoT devices and edge computing can mean for them.

But the reality is that almost every organization will eventually benefit from deploying IoT devices and automating data processing and decision-making at the edge. However, forward-thinking firms see the benefit in quick, configurable, and flexible deployments driven by no-code toolsets.

IoT Controller Use Cases:

- Manufacturing – IoT Controllers can monitor machinery, providing a stream of data about how assets are performing. If an asset falls out of calibration or exceeds indicative measurements, such as internal temperature, then an IoT Controller can power down the asset and trigger a workflow event requesting a manual inspection.

- Utilities – water professionals work with a variety of assets and legacy SCADA systems. IoT Controllers can augment monitoring and real-time data collection workflows, bringing together IT and OT systems with a business process management system.

- Laboratories – In many labs, samples must be kept at consistent temperatures. Over evenings and weekends, employees must manually check and record these temperatures. However, with a controller linked to digital workflows, this data collection is automated, and workflow alerts are triggered if the temperature strays from acceptable thresholds.

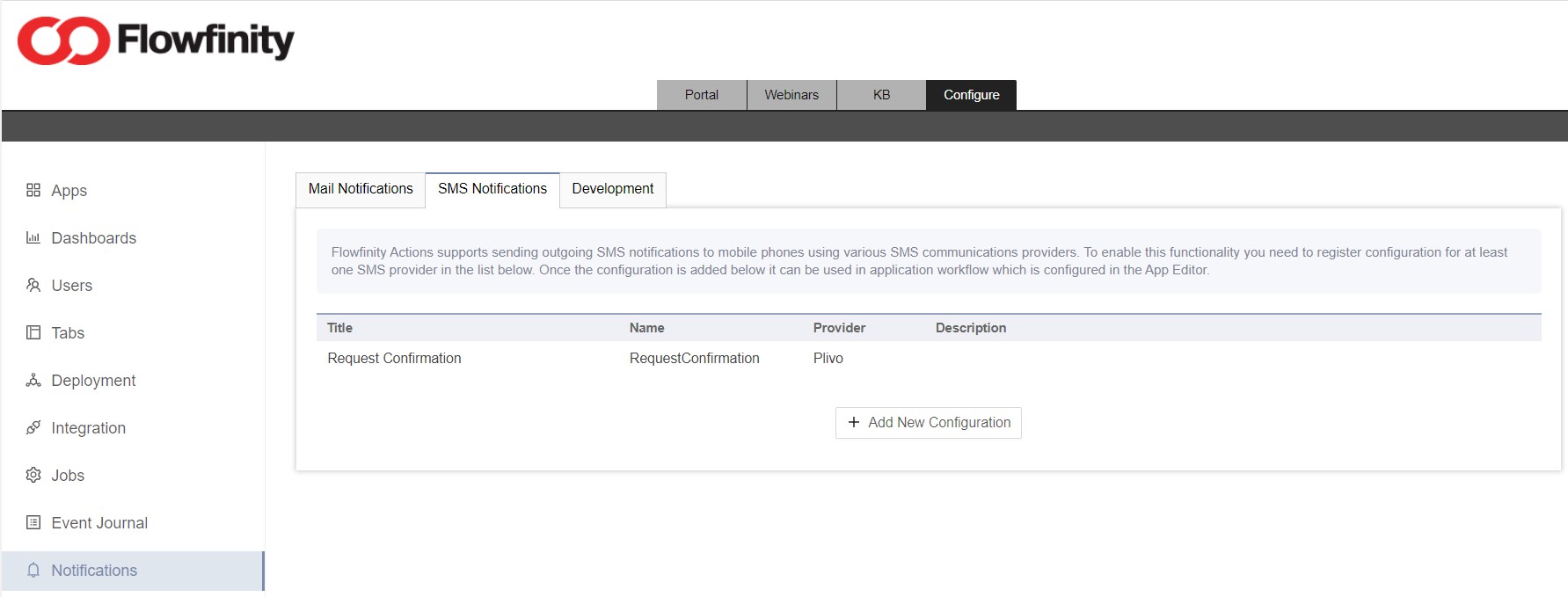

Custom SMS Notifications

You can now send outbound SMS text notifications directly from your workflows.

Flowfinity customers can now configure a connection to third-party SMS providers Twilio and Plivo. System admins and app builders can add multiple configurations and SMS templates to their applications, generating text notifications during workflows.

To learn more, visit our Knowledge Base article on Configuring SMS notifications in Flowfinity Actions.

In Case You Missed It

Looking to learn more about IoT and Edge Computing? Check out our comprehensive 3-part guide!

1. What It Means and Why It Matters

2. Benefits & Implementation Best Practices

3. Converging Operational Technology with IoT to Drive Automation

For more information about these new features, or how to leverage no-code IoT and Edge Computing to transform your business processes, please contact us.